Description

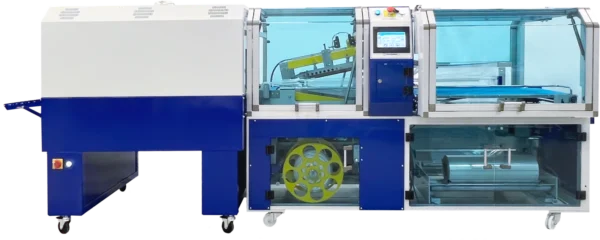

MECPACK FIVE STARS STD

- Electronic control panel with touch sensitive and intuitive

- operator interface to set and control all the machine functions

- in the best and simplest way (conceived by R&D Italdibipack).

- Possibility to memorize several working cycles with personalized parametres.

- Hot sealing bars (transversal and longitudinal) controlled by two

- independent electronic thermo-regulators.

- Working cycles and parameters setting controlled by microprocessor.

- Teflon coated sealing blade.

- Automatic pack bag length determined through horizontal or

- vertical photo-eye depending from the product shape.

- Multi-pack function (packing of more units in line).

- Infeed conveyor belt with a continuous or synchronised movement with the sealing bar.

- Counter

- Center seal function to save on the film width.

- Motorized film unwinder.

- Micro film performation during the film unwinding.

- Motorized scrap rewinder.

MECPACK FIVE STARS TOUCH

- Machine with electronic control based on a Mitsubishi 32 bIT PLC

- High speed data transmission software (latest Mitsubishi generation) which allows absolute precision of the set working parameters (head / tail / welding / speed times)

- Control of the retraction oven in all its working parameters directly from the display of the welding machine including automatic cooling at shutdown

- Speed regulation and control of inverter motor acceleration and deceleration directly from the display

- Belt conveyor working speed increased up to a maximum of 30 mt/1″

- Welding temperature and retraction oven control system from the PID method ON / OFF method, therefore greater precision and temperature maintenance

- Display control, in manual mode, of product advancement, welding, film pulling and product evacuation

- Diagnostics of alarms and failures and safety interventions readable on the display (over 40 different controls)

- Possibility to control the number of pieces produced in decrement with display of both partial and total production

- Over 100 programs that can be stored with all the related work parameters

- End of film control on/off

- Break of film control on/off

- Full scrap rewinder control

- Possibility of synchronization with external loading belt

- Possibility of continuous loading; the loading belt does not stop during welding

- Possibility of continuous loading; the exit belt does not stop during welding

- Possibility to perform multiple packs, that is, to count the products on arrival before welding the envelope

- Possibility to exclude the execution of the weld to allow the continuous passage of the products

- Possibility to execute a timed envelope, that is to say, instead of delegating the reading of the product length to the photocell, check it giving a time from the arrival of the product (useful for example in the case of strangely shaped products not completely readable by the photocells)

Machine made according to CE rules.

SPECIFICATIONS – MECPACK FIVE STARS STD

- Power supply voltage: 240/400 V – 3PH – N

- Installed power: 2.5 kW

- Overall dimensions: 2000 x 1000 x 1360 (h) mm

- Sealing bars dimensions: 600 x 500mm

- Max product height: 180 mm

- Conveyor belt speed: 22 m / min

- Productivity: up to 2200 pcs / h

- Max roll width: 600 mm x 250 mm

- Compressed air consumption: 6 Nl / p

- Compressed air: 6 bar

- Weight: 540 kg

- Electronic control panel (by R&D Italdibipack)

SPECIFICATIONS – MECPACK FIVE STARS TOUCH

- Power supply voltage: 240/400 V – 3PH – N

- Installed power: 2.5 KW

- Overall dimensions (LxWxH): 2000 x 1000 x 1360 mm

- Sealing bars dimensions: 600 x 500mm

- Max passage height: 180 mm

- Belt speed: 30 m / min

- Productivity: up to 2400 pcs / h

- Max film width: 600 x 250 mm

- Infeed conveyor height from the floor (machine on wheels): 790 mm

- Compressed air pressure: 6 bar

- Compressed air consumption: 6 N / l cycle

- Weight: 540 Kg

- Touch Display (Mitsubishi Software)

SPECIFICATIONS – MECPACK FIVE STARS BIG

- Power supply voltage: 240/400 V 3PH – N

- Installed power: 3 KW

- Overall dimensions (LxWxH): 2400 x 1200 x 1360 mm

- Sealing bars dimensions: 800 x 600 mm

- Min product dimensions (WxL): 100 x 100 mm

- Max passage height: 180 mm (220 mm on request)

- Belt speed: 22 m / min

- Productivity: up to 2200 pcs / h

- Max film width: 750 mm

- Roll diameter: 250 mm

- Min film width: 250 mm

- Infeed conveyor height from the floor (machine on wheels): 790 mm

- Compressed air pressure: 6 bar

- Compressed air consumption: 6 N / l cycle

- Electronic control panel (by R% D Italdibipack)

- Weight: 600 Kg

SPECIFICATIONS – TUNNEL 5525 EV

- Power supply voltage: 240/400 V- 3PH – N

- Installed power: 7 kW

- Dimensions: 1140 x 1000 x 1360 (h) mm

- Tunnel entrance: 550 x 250 mm

- Weight: 230 kg

note: Technical characteristics subjected to variations without previous notifications.

The output depends on the operator and on the overall dimensions of the products.

There are no reviews yet.