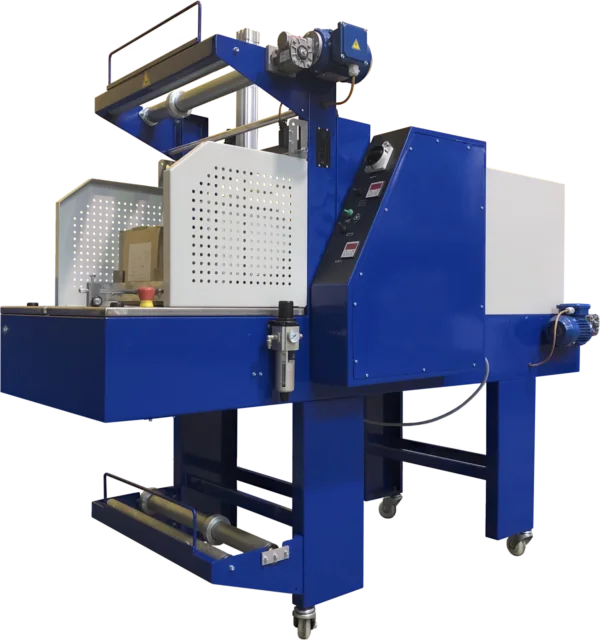

Description

MAIN CHARACTERISTICS COMMON TO ALL MODELS OF THE ECOFARD LINE

- Sealing time electronically adjustable

- In MB (monoblock) models the movement of the tunnel conveyor belt is synchronized with the sealing bar to drive easily also unstable products with no trays

- In BB (biblock) models the products remains in the sealing area until the next bundle moves forward and pushes it onto the conveyor belt of the tunnel which is in continuous motion

- Cooling fan at the tunnel exit (option on ECOFARD 500 SA)

- Tunnel steel zinc-coated mesh belt conveyor

- Air heating by finned resistances controlled by an electronic thermo-regulator

- Closed and forced air circulation with air flow adjustable by flaps in order to have the best shrinking

- Internal tunnel parts made by steel zinc-coated

- External powder painting

- Motorized bottom film unwinder (Optional for ECOFARD 500/700/900)

Optional:

- Vertical rollers to compress the film excess at the tunnel exit

- After-sealing-bar top-clamp to block unstable products

- Frequency AC engine controller for tunnel belt conveyor

- Tunnel belt conveyor 800 mm longer for wrapping bottles without any carton tray

- The machine works with monofolding/flat film) LLDPE

- Machine made according to CE rules

ECOFARD 500 SA MB

- Sealing Bar: lenght 500 x H 240 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 480 mm

- Max tunnel entrance: 480 X H 340 x 870 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 8 KW

- Motorized film unwinder: Superior roll

ECOFARD 500 SA EV MB

- Sealing Bar: lenght 540 x H 290 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 480 mm

- Max tunnel entrance: 470 X H 430 x 870 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 8 KW

- Motorized film unwinder: Superior roll

ECOFARD 700 SA MB

- Sealing Bar: lenght 700 x H 380 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 680 mm

- Max tunnel entrance: 700 X H 410 x 1300 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 17 KW

- Motorized film unwinder: Superior roll, Inferior roll optional

ECOFARD 700 SA BB

- Sealing Bar: lenght 700 x H 410 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 680 mm

- Max tunnel entrance: 700 X H 500 x 1300 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 17 KW

- Motorized film unwinder: Superior roll, Inferior roll optional

ECOFARD 700 AA MB

- Sealing Bar: lenght 700 x H 380 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 680 mm

- Max tunnel entrance: 700 X H 410 x 1300 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 17 KW

- Motorized film unwinder: Superior roll, Inferior roll optional

ECOFARD 700 AA BB

- Sealing Bar: lenght 700 x H 410 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 680 mm

- Max tunnel entrance: 700 X H 420 x 1300 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 17 KW

- Motorized film unwinder: Superior roll, Inferior roll optional

ECOFARD 900 AA BB

- Sealing Bar: lenght 900 x H 410 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 880 mm

- Max tunnel entrance: 900 X H 500 x 1400 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 24 KW

- Motorized film unwinder: Superior and inferior rolls

ECOFARD 1250 AA BB

- Sealing Bar: lenght 1250 x H 420 mm pneumatically working controlled by photo-eye

- Roll sizes: 250 x 1200 mm

- Max tunnel entrance: 1250 X H 500 x 2000 mm lenght

- Output: Up to 12 pz/min

- Power supply: 3 Ph + N + T | 220/380 V 27 KW

- Motorized film unwinder: Superior and inferior rolls

There are no reviews yet.