-

Read more

Seamers For Food Products

Zilli & Bellini seamers are suitable to seam a wide range of round containers filled with food or pet food products. Steam injection is available on request.

CONTAINERS

The machines can handle round metal and composite containers having a filling capacity up to 5 Kg.COVERS

The seamers can handle open top, easy open and easy-peel lidsCAPACITY

From 10 to 1200 c.p.m. according to the product and container size.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide, as an option, a system for the automatic cleaning of the seamerQuick View -

Read more

Seamers For Soft Drinks

Zilli & Bellini seamers are suitable to seam a wide range of round containers filled with soft drinks, beer and carbonated soft drinks. Under cover gassing systems are available on request.

CONTAINERS

The machines can handle round metal and aluminium containers.COVERS

The seamers can handle open top, easy open and easy peel lidsCAPACITY

From 10 to 1200 c.p.m. according to the product and container size..AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide, as an option, a system for the automatic cleaning of the seamerQuick View -

Read more

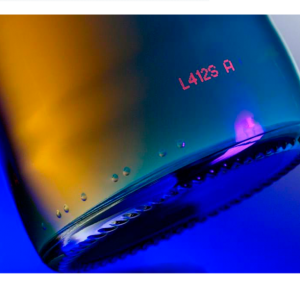

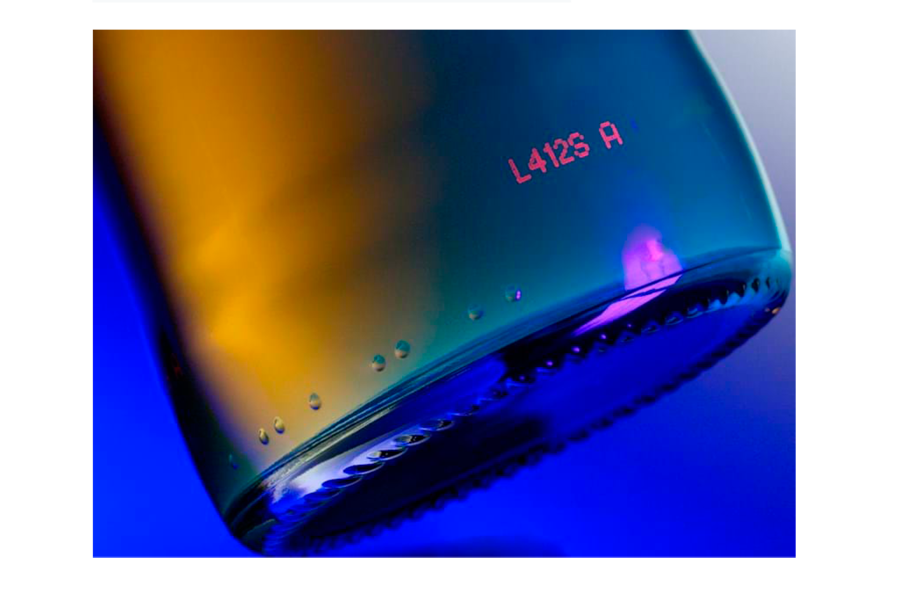

Security (UV Readable) Inks

Security (UV Readable) Inks

Inks which are near invisible in normal light but fluoresce violet or red under UV light. Suitable for anticounterfeiting and other discreet coding applications.

Quick View -

Read more

Spices Dosers

Zilli & Bellini spice dosers are suitable to handle a wide range of powdered and free flowing dry vegetables or spices.

CONTAINERS

The machines can handle round and non-round metal, glass, plastic and composite containers having a filling capacity up to 5 Kg.CAPACITY

From 10 to 1200 c. p. m. according to the product and container size.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide, as an option, a system for the automatic cleaning of the fillerPRODUCTS

- dried vegetables

- dried granulated products

- dried spices

MODELS

Several models are available based on speed, size and product.Quick View -

Read more

Static Steristeam Air Steam

Filled retort baskets are inserted into the STERISTEAM. The door is closed then locked automatically through a hydraulic cylinder. It is mechanically blocked throughout the entire cycle. Pre-heating of the enclosure is carried out by direct-steam-injection. Preheating temperature can be adjusted (e.g. 100°C – 0.2 bar) and air vent valve open. Adjustable period (e.g. 5 minutes). Heating phase can be started. Heat is produced in the enclosure by direct-steam-injection. Dissemination will be made between each basket. Graduated acting steam valve opening is monitored by MPI until the set temperature is reached, for instance 121°C. In this heating-up phase, the fan is on. The operation of the fan is continually monitored. Condensates are stored in the lower part of the enclosure. Once the scheduled duration of the bearing comes to an end : pre-cooling starts. It is performed by injecting cold water in the vessel via two lateral spray headers. This water accumulates at the lower section in addition to the condensates previously accumulated. The water level is controlled by a radar level and managed by MPI. Once the set temperature is reached, final cooling is carried out by cascading recycled water on the load. How does the cascading system operates ? Recycled water is made with steam condensates previously accumulated in previous phases as well as water make up. The mixture is pumped at the sterilizer lower section through the secondary circuit of an external heat exchanger (plates and gaskets), and returned on water distributor laid out on top of the load to cool.

Technical specifications :

Standard sizes:• 1,300 mm. corresponding to maximum size of manually operable basket (476 cans 4/4) and a capacity of 4 to 6 baskets.

• 1450 mm.

• 1600 mm.

• 1800 mm.

• 2000 mm.Types of packaging or products

• Prepared Pet food

• Small pouches.Quick View -

Read more

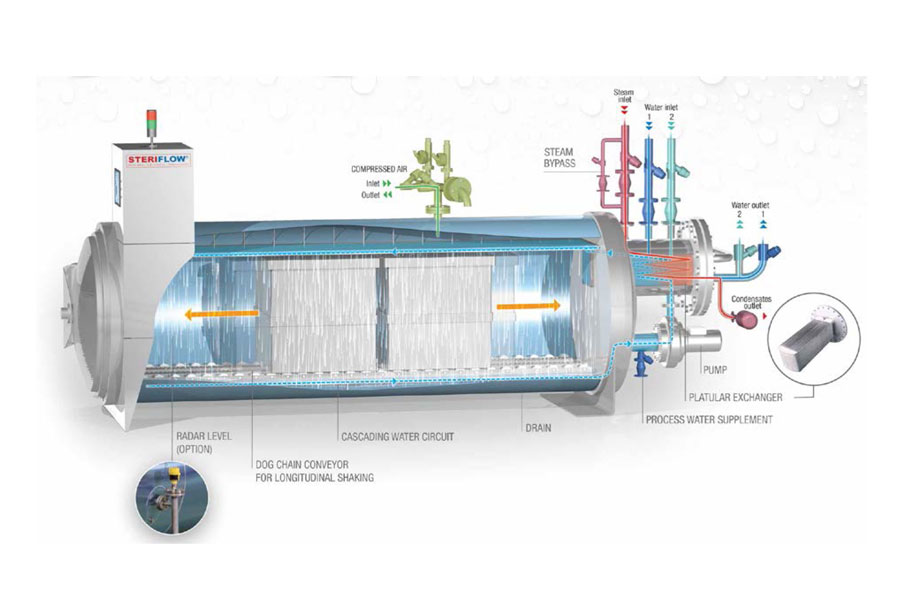

Steriflow Dali Cascading Water

With Dali Steriflow System, baskets of plastic milk jugs are moved back and forth horizontally at lowfrequency through the internal handling chain. Bottles must have a head space ; the milk is agitated by a bubble moving inside the bottle. This agitation is enough to avoid skin formation and browning during sterilization.

This is similar to rotation.The process used for this pasteurization is ideal for sterilizing your milk bottles, e. g. in plastic or glass packaging. You can also use a DALI autoclave for the sterilization of your sauces in your pocket and the sterilization of your drinks in cans.Technical specifications :

Standard diameters:

• 900 mm,

• 1,300 mm, this diameter corresponds to the maximum size of a manual basket (476 cans 4/4 cans) and a capacity of 1 to 9 baskets.

• 1,450 mm,

• 1,600 mm,

• 1,800 mm,

• 2,000 mm,

• With a capacity of 2 to 9 baskets according to diameter.Benefits

• We can achieve the same results as using the rotary process with liquid product. Dali is a less expensive and more flexible option as it is scalable to several package sizes in the same basket (unlike rotary where it is necessary to use different kind of baskets for each type of packaging).

• A small initial investment thus more affordable over the short term.

• We developed baskets specifically designed to this retort to provide an ease of use by operators.

• Low maintenance. Simple mechanics with a reduced number of parts.

• Packaging cooling is performed with sterile water.Types of packaging or products

• Dairy products, (do not caramelize thanks to low frequency shaking).

• Liquid products.

• Sauces.Quick View -

Read more

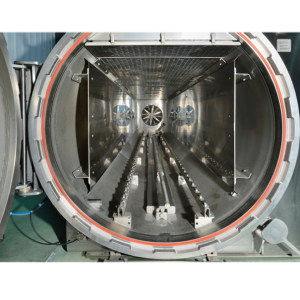

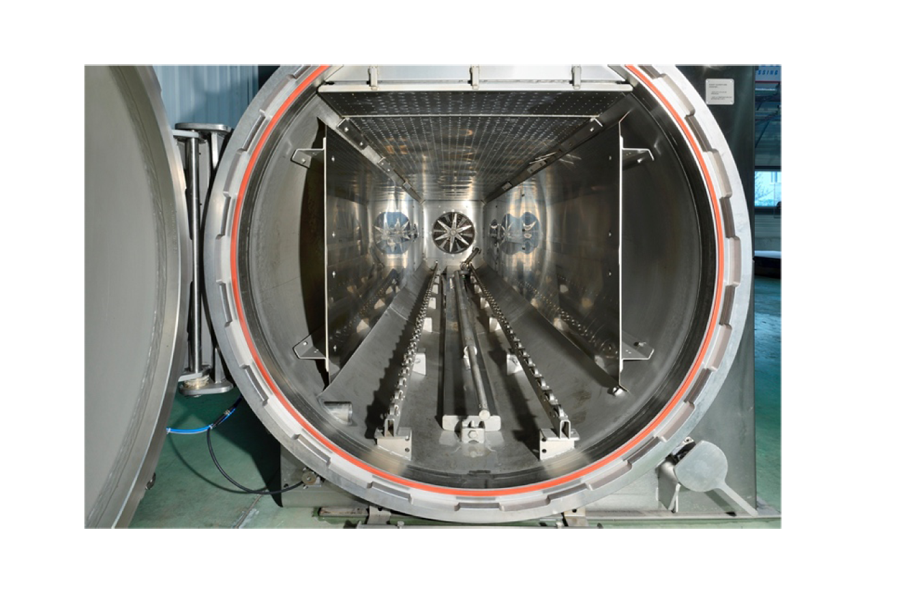

Steriflow Monofan Steristeam Air Steam

Static Monofan Air Steam

Filled retort baskets are inserted into the STERISTEAM. The door is closed then locked automatically through a hydraulic cylinder. The door is mechanically blocked throughout the entire cycle. Pre-heating of the enclosure is carried out by direct-steam-injection. Preheating temperature can be adjusted ((e.g. 100°C – 0.2 bar) and air vent valve open. Adjustable period (e.g. 5 minutes). Heating phase can be started. Heat is produced in the enclosure by directsteam-injection. Dissemination will be made between each basket. Graduated acting steam valve opening is monitored by MPI until the set temperature is reached, for instance 121°C. In this heating-up phase, the fan is on. The operation of the fan is continually monitored. Condensates are stored in the lower part of the enclosure. Once the scheduled duration of the bearing comes to an end : pre-cooling starts. It is performed by injecting cold water in the vessel via two lateral spray headers. This water accumulates at the lower section in addition to the condensates previously accumulated. The water level is controlled by a radar level and managed by MPI. Once the set temperature is reached, final cooling is carried out by cascading recycled water on the load. How does the cascading system operates ? Recycled water is made with steam condensate previously accumulated in previous phases as well as water make up. The mixture is pumped at the sterilizer lower section through the secondary circuit of an external heat exchanger (plates and gaskets), and returned on water distributor laid out on top of the load to cool.Technical specifications :

Standard diameters:

• 1,300 mm.

• 1,450 mm.

• 1,600 mm.

• 1,800 mm.

• 2,000 mm.Benefits

• Perfect reproducibility of the programmed cycles.

• Homogeneity of treatment with a powerful fan.

• A proven and reliable design with all common diameters.

• Powerful cooling system to optimize the cycle time.

• Ability to dry product at the end of the cycle.Product and packaging types

• Bags of saline solution

• Blister packQuick View -

Read more

Steriflow Robustex 90L Saturated Steam Foe NGO

Meets the requirements of the NGOs in the area of emergency operation

• Robustex retort is entirely manually operated.

• All stainless construction AISI 304L.

• It is used by many NGOs worldwide.Benefits

• Low investment.

• Optimum adaptation to very difficult conditions in the field.

• Very easy to use.Product and packaging types

• Surgical instruments.

• Textiles.

• Stainless steel parts.Quick View -

Read more

Steriflow Rotary Cascading Water

Rotary Steriflow

His stainless steel drum enables a product rotation. His particularly resilient mechanical design continued to evolve since the deposit of the 2nd patent in 1991 with a triangulated structure drum even more reliable. The strength of this drum has been widely tried, it is capable of supporting heavy packaging such as cans and jars. With Rotary Steriflow there will be nothing broken, no production shutdowns due to a weak manufacturing that can’t bear excessive weight. This retort has been specifically studied and designed to meet the needs of our customers regardless of the type of packaging used, lightest to heaviest.

Maximum capacity of 6 baskets.

Technical specifications :

Standard sizes:

• 1300 mm, corresponding to maximum size of manually operable basket (476 cans 4/4) and a capacity from 1 to 12 baskets.

• 900 mm,

• 1,600 mm, from 1 to 6 baskets.

• 1,800 mm, 4 and 5 baskets.\Power: Rotary Steriflow has a powerful pump shortening cycles which become more homogeneous. All products inside the retort get treated the same at any operating position. Shorter cycle can provide better performance.

Benefits

Some products shall be stirred during the sterilization cycle to:• Avoid browning to the edge of packaging.

• Mix water in rice pouch to ensure that it will not stick.

• For qualitative reasons, mixing may be useful…Baskets rotate under a heavy water streaming. This is a method for improving heat transfer into the packaging and reducing processing times and energy costs at the same time. Water streaming process is the most appropriate to rotation. When it is thought of as Air/steam, gas mixing should be facilitated by side plates such as static machine, but the drum space makes it impossible. This is causing major problems for temperature homogeneity in Air steam rotary autoclaves.

Types of packaging or products

• Cans

• Jars

• Pouches

• TraysApplications: Rotary Steriflow is generalized to better adapt to all type of packaging. All of them may be treated.

Quick View