-

Read more

Linx FSL20 & FSL50

Fibre laser technology for permanent coding on a wide range of materials

Permanently mark on a wide range of materials, including metal, rubber, plastic, and packaging foils. Very fine spot size creates excellent quality codes and makes Linx Fibre lasers ideal for marking very small components, or large amounts of information onto small areas. Text, machine readable codes, graphics and logos are all marked with extreme clarity for traceability; ideal for pharmaceutical, medical devices, automotive and electronics industries, as well as FMCG packaging.Quick View -

Read more

Linx General Purpose Black Inks

Linx General Purpose Black Inks

Our range of general-purpose black inks gives outstanding performance on most common materials, ideal for most general external packaging applications.

Quick View -

Read more

Linx IJ355 and IJ375

Linx IJ355 and IJ375

Linx IJ355 and IJ375 large character case coding machines offer a cost effective alternative to labels and pre-printed boxes. They can print text, logos and graphics up to 53mm (IJ355) or 70mm (IJ375) high onto porous substrates such as paper, card and wood.

Quick View -

Read more

Linx SL1

10 W Compact Laser Coder

Compact, cost effective coder, with the ability to print a wide range of message types, including multiple lines of high quality text, logos and machine readable codes. The Linx SL1 is a compact, cost effective coder designed to fit easily into production environments where space is constrained. An ultra-fast mirror system enables faster coding than other lasers in its class, while using much less laser energy but delivering 20% more power. No routine servicing or consumables mean the lifetime costs of the Linx SL1 laser are favorable compared to other types of printer, with no variable costs.Quick View -

Read more

Linx SLHP

Superior quality codes at some of the fastest speeds available on the market.

The Linx SLHP is a high power, 120 W CO2 laser which can code accurately at high speeds – for example in excess of 70,000 bottles per hour on high speed beverage production lines. The high power allows many different materials to be marked quickly and permanently –including traditionally hard-to-mark substrates such as glass, rubber and PET.Quick View -

Read more

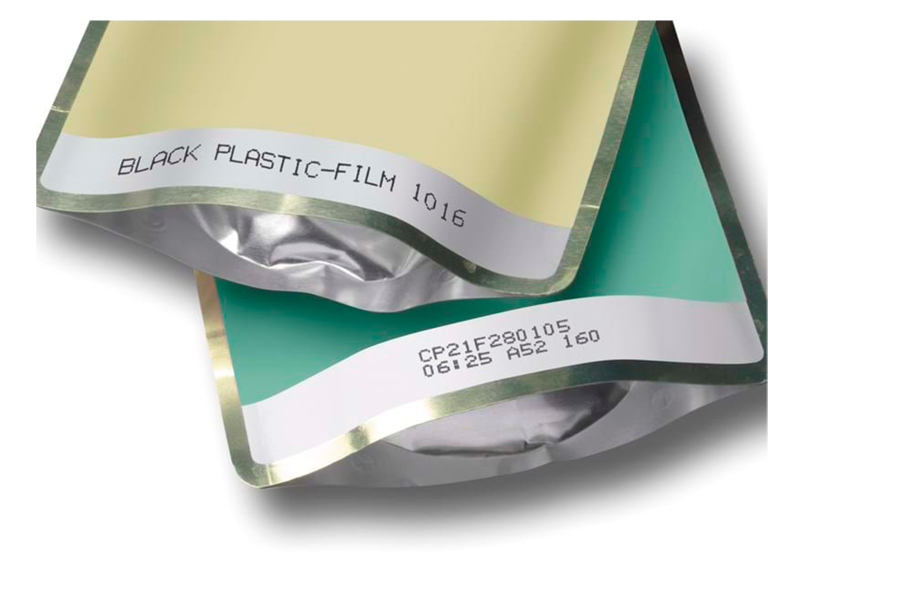

Linx Special Adherence Inks

Linx Special Adherence Inks

Designed for applications where production processes may challenge the adherence or durability of other inks. Inks for coding onto plastics and plastic films such as nylon, polyethylene, polypropylene (including untreated OPP and BOPP), and polyvinylchloride.

Quick View -

Read more

Linx TJ725

Complete, out-of-the-box coding solution

An ideal digital alternative to roller coders, valvejet and CIJ systems. High resolution coding onto boxes, trays and sleeves. The wide range of inks available provides reliability for a variety of packaging printing requirements. The Simply Smart Technology® incorporated into the Linx TJ725 ensures a more reliable and easy to use coding solution than any other thermal inkjet (TIJ) printer on the market. Start printing straight away without the need for installation engineers, training or maintenance. Code onto boxes, trays, sleeves and plastics with our extensive range of Linx TJ725 inks.

Quick View -

Read more

Monoblocks

Zilli & Bellini monoblocks are suitable to fill and close food products or flat soft drinks in round or shaped bottles made of glass and plastic materials.

The idea of the monoblock is to have more than one station installed in the same base frame: in this way it is possible to have an integrated system to clean, fill and close the containers.

One of the advantages of this solution is that the containers, after the filling phase, are moved in a synchronized monoblock in order to eliminate spillage of the product before the closing phase. We also eliminate any damage of the packaging.

A precisely timed drop of liquid Nitrogen (NL2) can be dosed into the headspace.

CONTAINERS

The monoblocks can handle round or shaped bottles made of glass and plastic materials.COVERS

The capping turret can close different kinds of cover made from different kinds of material in accordance with the Customer’s specificationsCONTAINER CLEANING

The empty containers can be cleaned with different kinds of cleaning media in accordance with the Customer’s specifications.CAPACITY

From 10 to 1200 c.p.m. according to the product and container size.PRODUCTS

It is possible to fill from liquid to very dense products with or without pieces.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide a system for the automatic cleaning of the monoblockMODELS

Several models are available based on the speed, size and product.Quick View -

Read more

Monoblocks For Ultraclean Filling

The monoblock is an integrated system to perform every phase in a controlled environment. All the processes are done in an area where there is an overpressure of sterile air (LAMINAR FLOW). In the upper part of the monoblock there is a stainless steel cover supported by the safety guards in order to reduce contamination coming from the outside during the critical processes of cleaning, filling and closing. A system of high efficiency HEPA filters introduce sterile air into the machine. After the filling phase, the containers are moved inside a synchronized monoblock without any product spillage before and during the closing phase.

A precisely timed drop of liquid Nitrogen (NL2) can be dosed into the headspace.CONTAINERS

The monoblocks can handle round or shaped bottles made of glass or plastic.COVERS

The capping turret can close different kinds of cover made from different kinds of material in accordance with the Customer’s specificationsCONTAINER AND COVER SANITIZING

The empty containers and the covers can be sanitized with different kinds of cleaning media in accordance with the Customer’s specifications.CAPACITY

From 10 to 1200 c. p. m. according to the product and container size.PRODUCTS

It is possible to fill from liquid to very dense products with or without pieces.AUTOMATIC CLEANING SYSTEM (C.I.P.)

Zilli & Bellini can provide a system for the automatic cleaning of the monoblockMODELS

Several models are available based on the speed, size and product.Quick View